ISO9001Certified Enterprises National High-tech

《Photocatalytic nanomaterials》

- Online mall |

- ENGLISH |

- 中文

Hotline:400-000-9809

Your current location:Home - News - Catalytic combustion treatment of sprayed organic waste gas: discussion of intake air concentration

Catalytic combustion treatment of sprayed organic waste gas: discussion of intake air concentration

|

Contact us

- Phone:400-000-9809

- Mobile phone:13318215621

- Fax:0757-86408626

- Mailbox:[email protected]

- Distribution centres:Six Changfu Urban Creative Industry Park in Luocun, Shishan Town, Nanhai City, Foshan City, Guangdong Province

ISO9001 certification national high and new technology enterprise disinfection products production enterprise hygiene license intellectual property management system certification of guangdong high quality UV lamp, UV germicidal lamp sterilization lamp, household electrical appliances disi

ISO9001认证企业 国家高新技术企业 消毒产品生产企业卫生许可证 知识产权管理体系认证证书

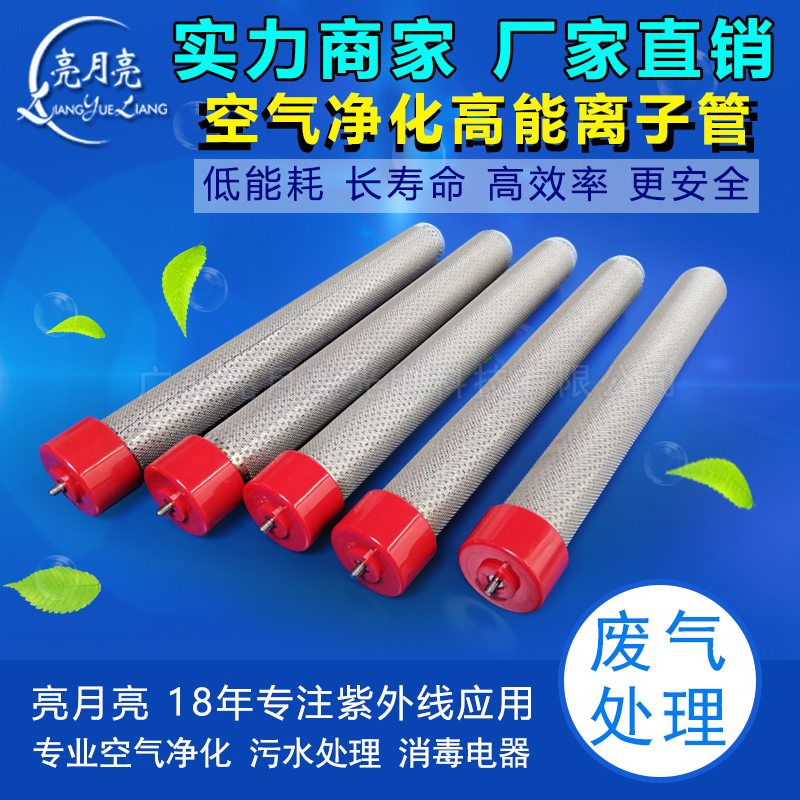

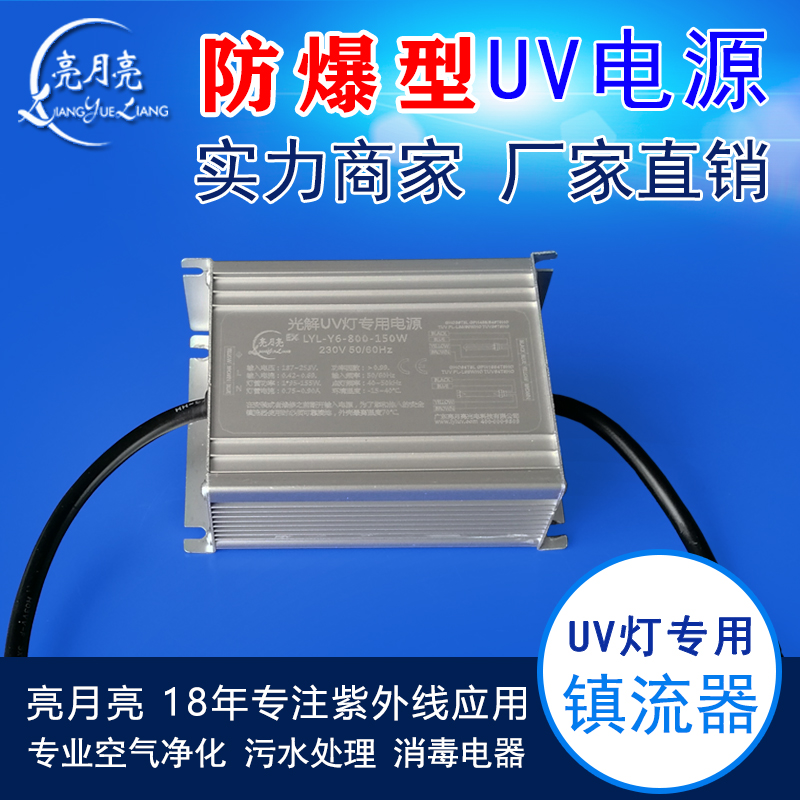

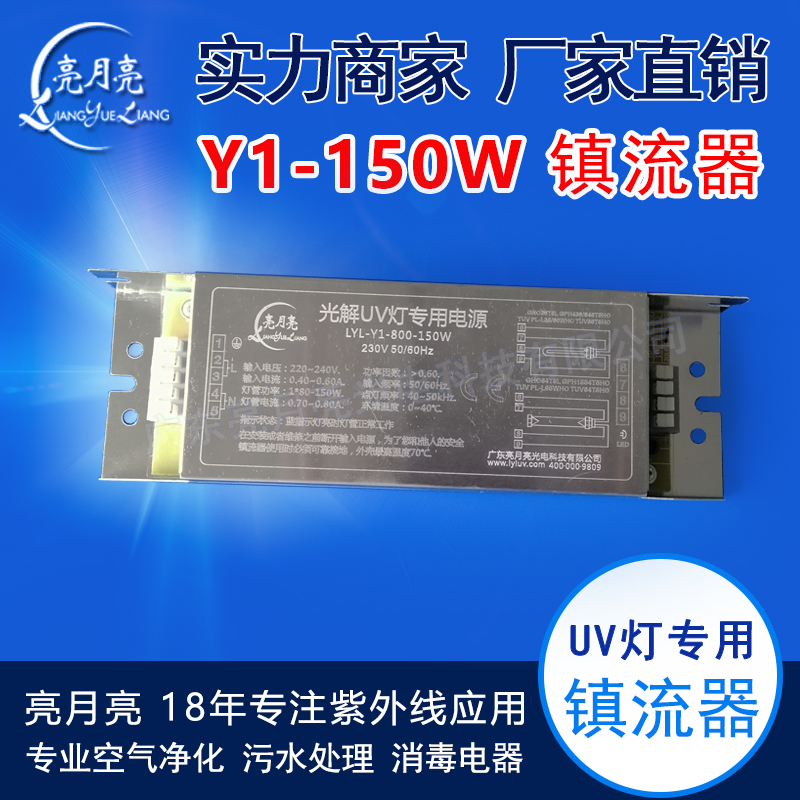

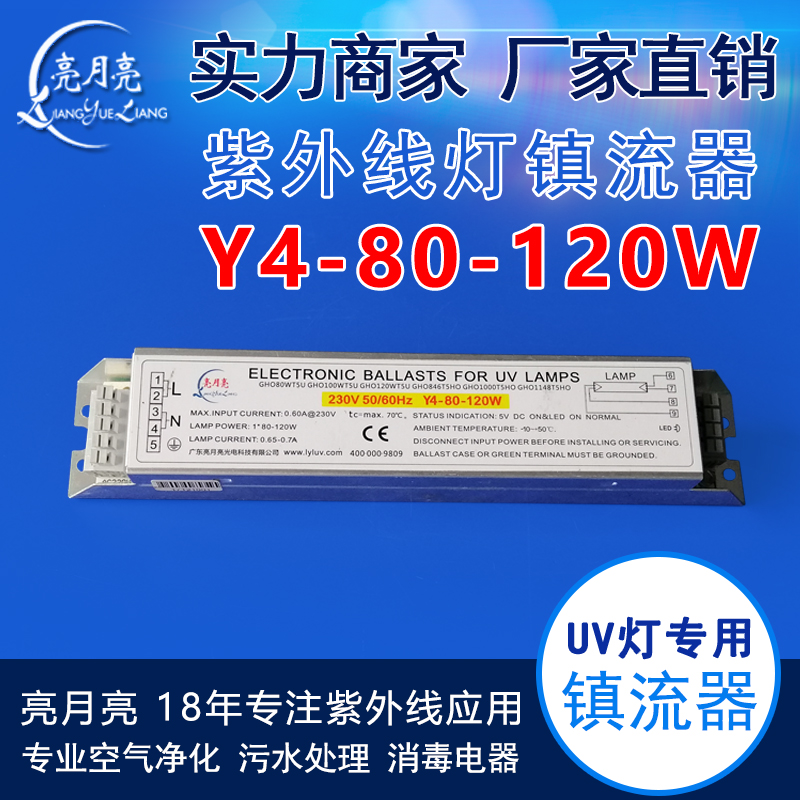

广东优质UV灯,紫外线杀菌灯消毒灯,家用电器消毒灯,高能离子管,UV光催化网,紫外线镇流器

废气处理UV光催化技术方案,废气处理设备光解使用指南,污水消毒应用方案 15019601356 186666550579

2020广东亮月亮光电科技有限公司 版权所有 备案 粤ICP备17031447号 [email protected]

2020广东亮月亮光电科技有限公司 版权所有 备案 粤ICP备17031447号 [email protected]

About Us

About Us Vision

Vision Corporate culture

Corporate culture Corporate video

Corporate video Service mode

Service mode

1554mm waste gas sewage treatment ultraviolet germicidal lamp

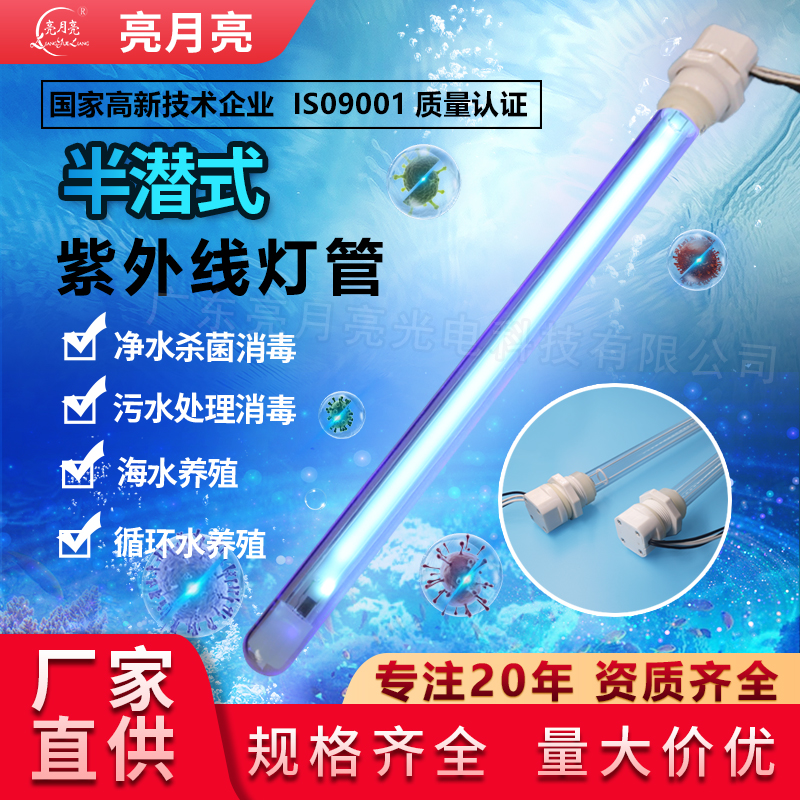

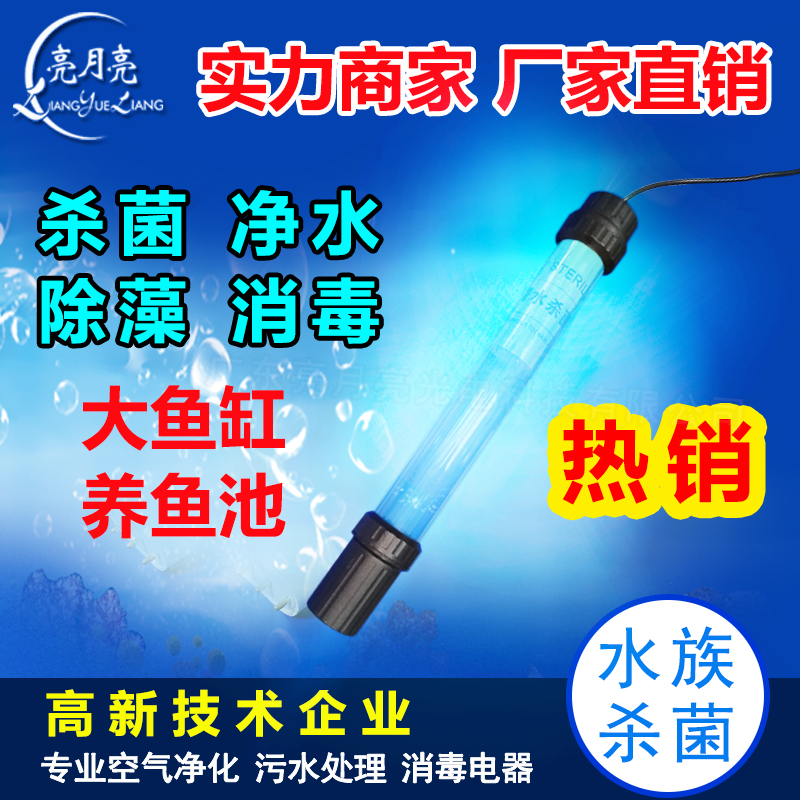

1554mm waste gas sewage treatment ultraviolet germicidal lamp Aquarium Aqua UV germicidal lamp

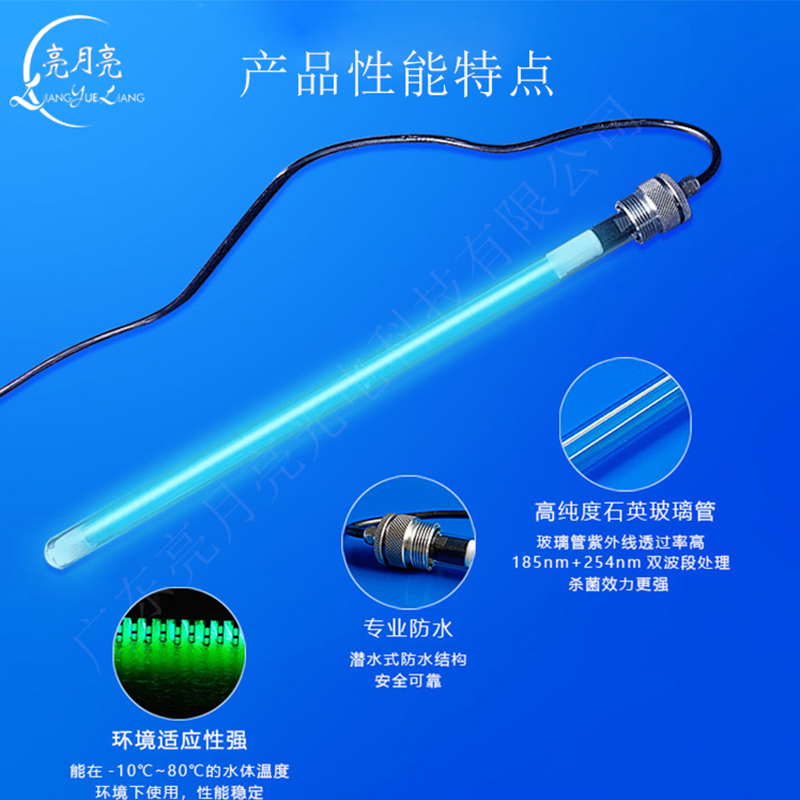

Aquarium Aqua UV germicidal lamp Metal head 100W full submersible water treatment lamp

Metal head 100W full submersible water treatment lamp