| |

| Introduction of technology dry goods 丨 oxidation ditch process |

| Click:1990 Issued:lyluvcom Release time: 2018/5/23 |

|

The oxidation ditch, also known as the continuous loop reactor, is a variant of the activated sludge process. The oxidation ditch process has been widely used in the field of urban domestic sewage and industrial wastewater treatment, and has become the dominant activated sludge sewage treatment technology.

Especially in China, the construction of sewage treatment plants is mainly small and medium-sized, and various oxidation ditch processes are widely used. Among them, the Obel oxidation ditch is widely used, and the DE and T multi-ditch alternates are applied in medium and high concentration sewage treatment plants. More, while the Carrousel Oxidation Ditch is dominated by loans.

The oxidation ditch is a wastewater biological treatment technology developed by the Dutch Institute of Health Engineering in the 1950s. It is a modification of the activated sludge process and is a special form of delayed aeration. The basic feature is that the aeration tank is closed, the annular runway type, the pool body is long and narrow, the pool depth is shallow, and a surface aeration device is arranged in the groove. The wastewater and activated sludge and various microorganisms are mixed and circulated in the ditch to complete the nitrification and denitrification treatment of the wastewater.

The biological oxidation ditch combines the characteristics of a fully mixed, push-flow and oxidation pond. It has the characteristics of high purification degree, impact resistance, stable and reliable operation, simple operation, convenient operation and management, simple maintenance, low investment and low energy consumption. The oxidation ditch forms aerobic zone, anoxic zone and anaerobic zone in space, and has good nitrogen removal function.

1. Overview of oxidation ditch process

1.1 Basic principle and main design parameters of oxidation ditch process

The oxidation ditch, also known as the oxidation ditch, is named after its structure is a closed circular ditch. It is a variant of the activated sludge process. Because sewage and activated sludge continuously circulate in the aeration channel, some people call it “circulating aeration tank” and “endless aeration tank”. The oxidation ditch has a long hydraulic retention time and a low organic load, which is essentially a delayed aeration system. The following are the main design parameters of the general oxidation ditch method:

Hydraulic retention time: 10-40 hours;

Sludge age: generally greater than 20 days;

Organic load: 0.05-0.15kg BOD5 / (kgMLSS.d);

Volume load: 0.2-0.4kg BOD5/(m3.d);

Activated sludge concentration: 2000-6000mg/l;

Average flow rate in the ditch: 0.3-0.5m/s

1.2 Technical characteristics of oxidation ditch:

The oxidation ditch uses a Cintinuous Loop Reactor (CLR) as a biological reaction tank, and the mixed liquid is continuously circulated in a closed aeration channel in the reaction tank, and the oxidation ditch is usually used under delayed aeration conditions. The oxidation ditch uses a direction-controlled aeration and agitation device to deliver a horizontal velocity to the material in the reaction cell, thereby circulating the agitated liquid in the closed channel.

The oxidation ditch generally consists of a groove body, an aeration device, an inlet and outlet device, a diversion flow and a mixing device. The planar shape of the groove body is generally annular, or may be rectangular, L-shaped, circular or other shapes, and the shape of the groove end face is mostly Rectangular and trapezoidal.

The oxidation ditch process has a long hydraulic retention time, a low organic load and a long sludge age. Therefore, compared with the traditional activated sludge method, the adjustment tank, the primary sedimentation tank, the sludge digestion tank, and some of the secondary sedimentation tanks can be omitted. The oxidation ditch can ensure a better treatment effect, which is mainly due to the ingenious combination of the CLR form and the specific positioning arrangement of the aeration device. The oxidation ditch has unique hydraulic characteristics and working characteristics:

1) Oxidation ditch combines the characteristics of push flow and complete mixing to effectively overcome short flow and improve buffering capacity. Usually, the inflow is arranged upstream of the oxidation ditch aeration zone, and the outflow is arranged at the upstream point of the inflow point. The influent is well mixed and dispersed in the circulation through the aeration zone, and the mixture continues to circulate around the CLR again. In this way, the oxidation ditch is pushed in a short period of time (such as a cycle), and in a long-term (such as multiple cycles) in a mixed state. The combination of the two, even if the inflow is subjected to at least one cycle and basically eliminates the short flow, it can provide a large dilution factor and improve the buffering capacity. At the same time, in order to prevent sludge deposition, it is necessary to ensure sufficient flow velocity in the ditch (generally the average flow velocity is greater than 0.3 m/s), and the residence time of the sewage in the ditch is longer, which requires a large circulation flow in the ditch (generally It is several times or even tens of times the flow rate of sewage inflow. The sewage entering the ditch is immediately mixed and diluted by a large amount of circulating liquid. Therefore, the oxidation ditch system has a strong impact load resistance, and is also good for organic substances that are not easily degraded. Processing capacity.

2) The oxidation ditch has an obvious gradient of dissolved oxygen concentration, which is especially suitable for the nitrification-denitrification biological treatment process. The oxidation ditch is completely mixed as a whole, while the liquid flow keeps pushing forward, and the aeration device is positioned. Therefore, the dissolved oxygen concentration in the aeration zone is upstream and then along the groove length. Gradually, there is a significant concentration gradient, and the dissolved oxygen concentration in the downstream zone is very low, basically in anoxic state. The oxidation ditch design can arrange the aerobic zone and the anoxic zone to achieve the nitrification-denitrification process as required. Not only can the oxygen in the nitrate be used to satisfy a certain oxygen demand, but also the alkalinity consumed in the nitrification process can be supplemented by denitrification. These are conducive to saving energy and reducing or even eliminating the amount of chemicals that need to be added during the nitrification process.

3) Uneven distribution of power density in the oxidation ditch is conducive to oxygen mass transfer, liquid mixing and sludge flocculation. The power density of conventional aeration is generally only 20-30 watts/m3, and the average velocity gradient G is greater than 100 sec-1. This not only facilitates the transfer of oxygen and liquid mixing, but also facilitates the full cutting of the flocculated sludge particles. When the mixed solution reaches the late stage of the aerobic zone through the smooth conveying zone, the average velocity gradient G is less than 30 sec-1, and the sludge still has the opportunity of re-flocculation, thus also improving the flocculation performance of the sludge. Units that need to be treated with sewage can also consult enterprises with similar experience in wastewater treatment on the sewage project service platform.

4) The overall power density of the oxidation ditch is low, which saves energy. Once the mixture of oxidation ditch is accelerated to the average flow rate in the ditch, it is only necessary to overcome the head loss along the course and curve for the maintenance cycle, so the oxidation ditch can maintain the mixture flow at a much lower overall power density than other systems. Activated sludge suspension state. According to some foreign reports, the oxidation ditch is 20%-30% lower than the conventional activated sludge process.

In addition, according to statistics at home and abroad, compared with other sewage biological treatment methods, the oxidation ditch has the advantages of simple treatment process, convenient super-management, good effluent quality, strong process reliability, low capital investment and low operating costs.

1.3 Innovation of aeration equipment:

Aeration equipment has a key impact on the treatment efficiency, energy consumption and treatment stability of the oxidation ditch. Its role is mainly reflected in the following four aspects: supplying oxygen to the water; advancing the water flow, making the water flow in the pool for circulation; ensuring the ditch The activated sludge is in suspension; the oxygen, organic matter and microorganisms are thoroughly mixed. In response to the above requirements, aeration equipment has also been improved and improved. Conventional oxidation ditch aeration equipment has a horizontal shaft aeration device and a vertical shaft aeration device.

1) The horizontal axis aerator is a rotating brush and a turntable. Among them, the rotating brush is more common, and the rotating brush alone can only meet the oxidation ditch with shallow water depth, and the effective water depth is not more than 2.0-3.5 meters. As a result, the traditional oxidation ditch is shallow and the floor space is large. In recent years, the underwater propeller has been developed to cooperate with the rotating brush to solve this problem. For example, the Shandong Gaomi Wastewater Treatment Plant has an effective water depth of 4.5 meters, ensuring that the average flow velocity in the ditch is greater than 0.3 m/s and the bottom flow velocity is not less than 0.1 m/ In seconds, the area occupied by the oxidation ditch is greatly reduced, and the application of the rotating brush technology is quite mature. However, due to its low oxygen supply rate and high energy consumption, it is gradually replaced by another advanced aeration technology.

2) Vertical axis surface aerator, various types of surface aerators can be used for oxidation ditch, generally installed in the turn of the ditch, this aeration device has a large lifting capacity, the oxidation ditch water depth can reach 4 -4.5 m, such as the famous Carrousel oxidation ditch developed by PHV in the Netherlands in 1968. The low-speed surface impeller is fixed in the direction of one end of the vertical axis. When the impeller rotates, in addition to supplying oxygen to the sewage, the water in the ditch can be oriented in a certain direction. Circulating flow. The table exposure equipment is cheaper, but the energy consumption is large and easy to malfunction, and maintenance is difficult.

3) Jet aeration, in 1969, Lewrnpt et al. created the first experimental jet aeration oxidation ditch (JAC). The foreign jet aeration is mostly pressure-supply, while the domestic is usually self-priming air, the advantages of JAC. It is the width of the oxidation ditch and the depth of the water is not limited, it can be used for deep water aeration, and the utilization rate of oxygen is high. At present, the largest JAC in Linz, Austria, has a treatment flow rate of 172,000 tons/day and a water depth of 7.5 meters.

4) Microporous aeration, nowadays more microporous aeration devices are used, and the porous air diffusion device overcomes the problem of large pressure loss and easy clogging of the device, and the oxygen utilization rate is high. The more widely it comes.

5) Other aeration equipment, including some new aeration propulsion equipment, such as the new aerator for compound leaf throttling, high oxygen utilization rate, floating on the water surface, easy to overhaul, oxygenation capacity up to 7 meters underwater, pushing It has a strong ability to meet the requirements of aeration and aeration integration of oxidation ditch, and at the same time it can satisfy the oxygenation and pushing at the bottom of the oxidation ditch.

Oxidation ditch has developed rapidly both at home and abroad. There are thousands of oxidation ditch sewage plants in Europe. In the country, the advanced technology of introducing foreign oxidation ditch in urban sewage and industrial wastewater began in the late 1980s, from the original daily processing capacity of 3,000 cubic meters to the current 100,000. More than ton of sewage treatment plants have become more common, and the oxidation ditch process has become the main process of urban sewage treatment in China.

2. Oxidation ditch denitrification and phosphorus removal process

2.1 Denitrification and dephosphorization of traditional oxidation ditch

The denitrification of the traditional oxidation ditch mainly utilizes the heterogeneity of the dissolved oxygen distribution in the ditch. Through reasonable design, the aerobic zone and the anoxic zone of the alternating cycle are generated in the ditch, thereby achieving the purpose of denitrification. Its greatest advantage is the removal of organic matter and total nitrogen in the same trench without the addition of a carbon source, and is therefore very economical. However, in the same ditch, the volume and dissolved oxygen concentration of the aerobic zone and the anoxic zone are difficult to accurately control, so the effect on nitrogen removal is limited, and it has little effect on phosphorus removal. In addition, in the traditional single-channel oxidation ditch, microorganisms in the aerobic-anoxic-aerobic transient and frequent environmental changes make the nitrifying bacteria and denitrifying bacteria groups not always in the optimal growth and metabolism environment. This also affects the processing capacity of the unit volume structure.

With the reverse of the oxidation ditch process, there are currently some representative forms in engineering applications: multi-channel alternating oxidation ditch (such as three-channel type, five-channel type) and its improved, Carrousel oxidation. Ditch and its improved, Orbal oxidation ditch and its improved, integrated oxidation ditch. They all have a certain ability to remove nitrogen and phosphorus.

2.2. Nitrogen and phosphorus removal of PI type oxidation ditch

PI (Phase Isolation) type oxidation ditch, which is an alternating and semi-alternating oxidation ditch, was developed in Denmark in the 1970s, including DE type, T type and VR type oxidation ditch, with the effluent of sewage treatment plants in various countries. Nitrogen and phosphorus requirements are becoming more and more strict, so the development of a functionally enhanced PI-type oxidation ditch, mainly developed by Kruger in cooperation with the Demmark Institute of Technology, is called Bio-Denitro and Bio-Denipho processes. It is based on the principle of biological nitrogen and phosphorus removal by A/O and A2/O to create anoxic/aerobic, anaerobic/anoxic/aerobic process environment to achieve the purpose of biological nitrogen and phosphorus removal.

2.2.1 DE type, T type oxidation ditch denitrification process

The DE type oxidation ditch is a double ditch system, and the T type oxidation ditch is a three ditch system. The operation modes are similar. They are all the switching of the flow direction of the water flow through the distribution well, the opening and closing of the door and the speed regulation of the aeration brush. Alternate nitrification and denitrification conditions are created in the ditch to achieve the purpose of denitrification. The difference is that the DE type oxidation ditch system is divided into a secondary settling tank and an oxidation ditch, and has an independent sludge returning system; and the two sides of the T-shaped oxidation ditch are used as a sedimentation tank.

2.2.2 VR type oxidation ditch denitrification process

The VR oxidation ditch type is like a normal circular runway. There is a straight wall structure of a small island in the center. The oxidation ditch is divided into two volumes of equal volume. The horizontal form is the reverse English letter C, and the sewage treatment passes through the two gates. The two outflows alternately open and close for continuous and constant water level operation.

2.2.3 PI type oxidation ditch simultaneous nitrogen and phosphorus removal process

Alternate oxidation ditch is good in denitrification effect. In order to achieve the dephosphorization effect, the corresponding anaerobic zone or structure is usually set in front of the oxidation ditch or the operation mode is changed. According to the actual operation experience at home and abroad, this simultaneous nitrogen and phosphorus removal process can achieve good nitrogen and phosphorus removal effects as long as it is well controlled during operation.

Xi'an Beishiqiao Wastewater Treatment Center adopts DE-type oxidation ditch system with nitrogen and phosphorus removal (pre-added anaerobic tank). The treatment capacity of the first-stage project is 150,000 cubic meters per day. The measured results of various stages of treatment show that DE The type of oxidation ditch has a significant effect on the treatment of urban sewage. The total removal efficiencies of COD, TN and TP were 87.5%-91.6%, 63.6%-66.9%, 85.0%-93.4%, effluent TN was 9.0-10.1mg/l, TP was 0.42-0.45mg/l, effluent quality It is superior to the national secondary effluent discharge standard.

The above three types of PI type oxidation ditch denitrification and dephosphorization process have the speed regulation of rotating brush, the frequent switching of the opening and closing of the valve and the water outlet, the high automation requirement and the low utilization rate of the rotating brush, so in the economically underdeveloped area Very limited.

2.3 Aubel oxidation ditch nitrogen and phosphorus removal process

Orbal oxidation ditch is abbreviated as concentric circle. It is also divided into separate types. It has a separate secondary settling tank. It uses a rotating disc aeration and a deep ditch. Its denitrification effect is very good, but the phosphorus removal efficiency is not high enough. An anaerobic tank is also required.

The application is mostly composed of an elliptical three-ring channel. The three loops use different DOs (for example, the outer ring is 0, the middle ring is 1, and the inner ring is 2), which is beneficial to nitrogen and phosphorus removal. The use of rotating disc aeration, water depth is generally 4.0 - 4.5m, power efficiency and rotating brush close, has been applied in the urban sewage treatment plant in Weifang, Beijing, Huangcun and Hefei Wang Xiaoyu.

2.4 Carrousel oxidation ditch nitrogen and phosphorus removal process

2.4.1 Traditional Carrousel Oxidation Ditch Process

The Carrousel oxidation ditch was developed in 1967 by the Dutch company DHV. Its purpose is to satisfy the problem of mixing the mixed liquid in the deep oxidation ditch and maintaining high mass transfer efficiency, so as to overcome the defects of shallow shallow ditch and poor mixing effect. Up to now, more than 850 Carrousel oxidation ditch systems have been operating in the world. The practice has proved that the process has the advantages of low investment, high processing efficiency, good reliability, convenient management and low operation and maintenance costs. The Carrousel oxidation ditch uses a vertical table aerator. The aerator is installed at one end of the ditch, thus forming an oxygen-rich zone near the downstream of the aerator and an anoxic zone upstream, which is beneficial to bioflocculation and makes the activated sludge easy to settle. Design effective water depth 4.0-4.5 meters, in the ditch

|

|

About Us

About Us Vision

Vision Corporate culture

Corporate culture Corporate video

Corporate video Service mode

Service mode

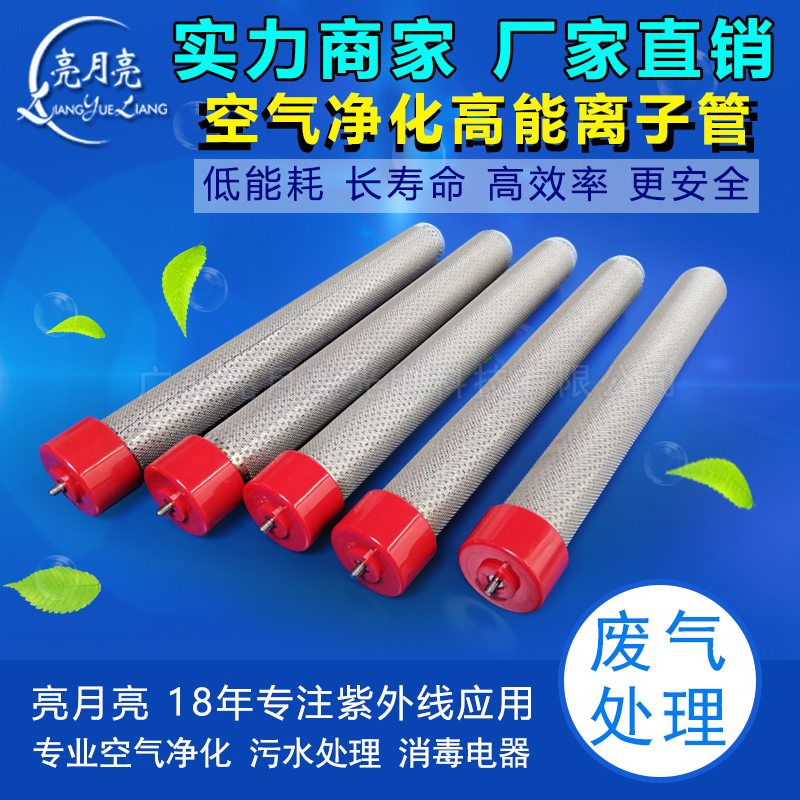

1554mm waste gas sewage treatment ultraviolet germicidal lamp

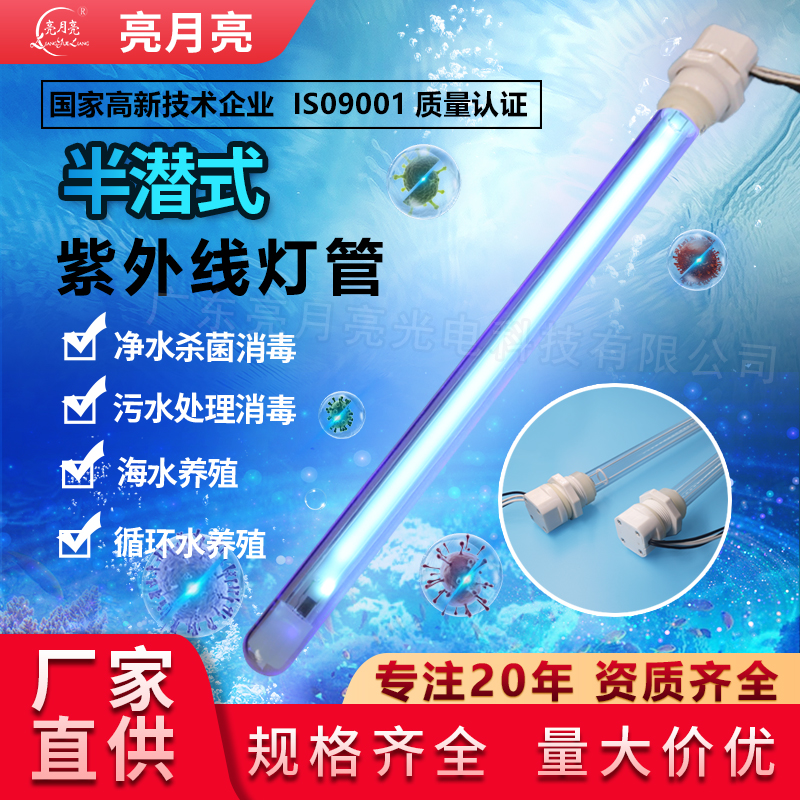

1554mm waste gas sewage treatment ultraviolet germicidal lamp Aquarium Aqua UV germicidal lamp

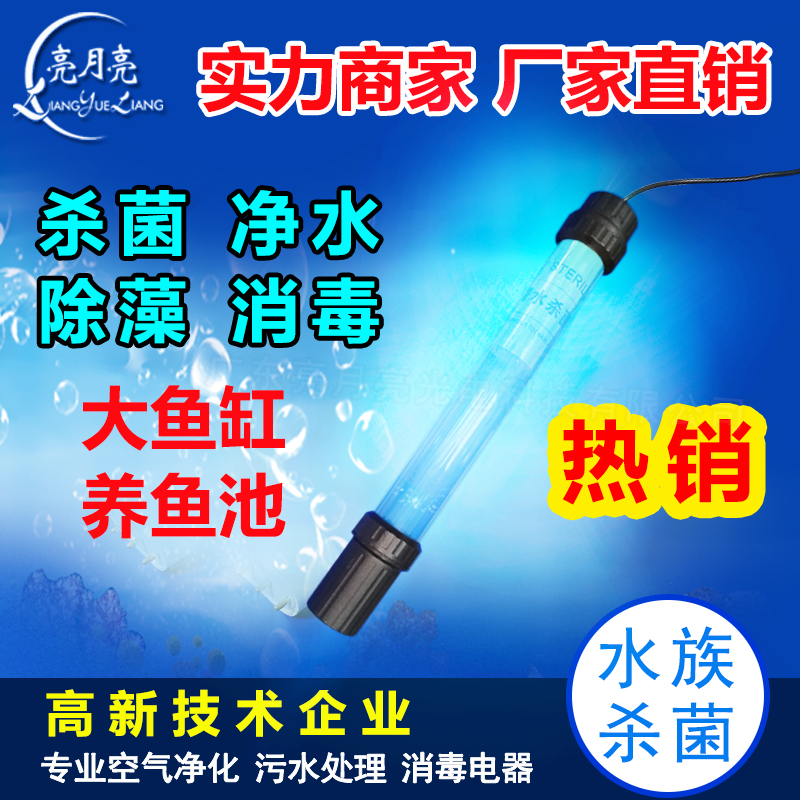

Aquarium Aqua UV germicidal lamp Metal head 100W full submersible water treatment lamp

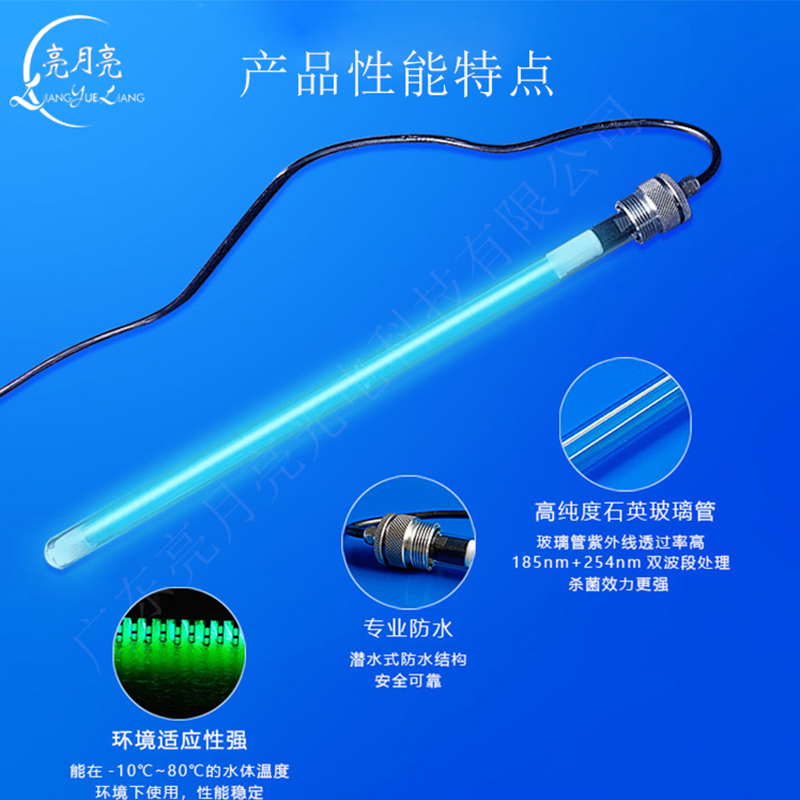

Metal head 100W full submersible water treatment lamp