| |

| These 31 super practical water treatment classics, you must know |

| Click:1721 Issued:lyluv.com Release time: 2018/10/20 |

|

The best way is to make the most of the fragmentation time. Today, we have prepared 31 very practical water treatment knowledge points, each of which is independent of each other. You can look at it in combination with your own specific perspective.

1. Several basic concepts in water treatment systems: TDS, SDI, LSI, KSP

TDS: total dissolved solids (general and salinity similar)

SDI: The pollution index is a measure of the pretreatment effect of the system, SDI < 6.7. For well water, the reverse osmosis unit requires SDI <5 for the influent SDI.

LSI: Langelier Saturation Index, Langelier index is a measure of the tendency of scale for reverse osmosis devices. LSI=0, the system has no tendency to foul and corrosion. LSI>0, the system has a tendency to scale; LSI<0, the system has a tendency to corrode.

For reverse osmosis systems, the LSI value requirement is not greater than zero. The LSI value of the system can be reduced by adding acid, or it can be reduced by reducing the system water recovery rate.

Ksp: Solubility balance constant. The reverse osmosis device selectively permeates the solvent and solute in the raw water, and concentrates on the concentrated water side due to the decrease of the solvent. When the concentrated solids are concentrated, the concentration is greater than the solubility equilibrium constant. It will crystallize and precipitate, which will cause harm to the reverse osmosis device. Increasing the solubility equilibrium constant of the system can be achieved by adding a scale inhibitor, which can increase the solubility of dissolved solids.

2. How can the LSI index be effectively controlled?

To effectively control the system's LSI index, you can do the following:

1) The system LSI index can be lowered by reducing the system water recovery rate.

2) The system LSI index can be lowered by adding acid.

3) The solubility of dissolved salts in the system can be increased by adding the corresponding agents, such as adding TRISPE1000 scale inhibitor.

4) Water can be introduced by reducing or pre-removing easily structured ions in the water, such as by softening the column softening system.

3. What are the pre-processing equipment?

Pretreatment equipment includes: mechanical filter, high efficiency fiber filter, activated carbon filter, precision filter, ultrafiltration, microfiltration, sodium ion softener, iron and manganese removal filter, dosing device, raw water tank, aeration tank .

4. What are the pre-desalting equipment?

The pre-desalting device has an electrodialysis device and a reverse osmosis device.

Electrodialysis unit

Reverse osmosis device

5. What are the deep demineralization equipment?

There are deep demineralizers including anion exchangers, cation exchangers, mixed ion exchangers, distillation units, and EDI units.

6. How is the mechanical filter selected? What is the working principle?

The selection of mechanical filters is based on the total amount of water in the system to choose the size of the filter and the combination (one mechanical filter is not enough to select multiple parallel and spare), the filler in the mechanical filter is made up of many Refined quartz sands of different particle sizes are arranged in strict order from large to small, thus forming a good quartz sand grading.

When the filter is just put into use, the filtering effect is often not very good, because the filter does not form a “bridge” at the beginning. The so-called “bridge” refers to an intercepting network composed of suspended solids in the water. The intercepting net intercepts. The suspended matter corresponding to its particle size, and then intercepts the suspended matter with a smaller particle size, forms a reverse-grained filtration process that first intercepts large particulate matter and then intercepts small particulate matter.

Once the filter forms a “bridge”, the filtering effect is very good. As the time of operation is longer, the filtering accuracy is higher and higher, the intercepting net is getting thicker and thicker, and the pressure difference between the inlet and outlet is getting larger and larger. When the pressure difference reaches 1kg. /cm2 The filter should be backwashed.

In the process of backwashing, it is better to use compressed air to scrub quartz sand. The general engineering experience is that mechanical filters with diameter less than 2500mm do not need compressed air; mechanical filters with diameters larger than 2500mm must be scrubbed with compressed air. A satisfactory cleaning effect can be achieved; the backwashing flow is typically 3-4 times the design capacity of the filter.

Quartz sand filter

Activated carbon filter

Fiber ball filter

Multi-media filter

Fiber bundle filter

7. How is the precision filter selected? How many ways does the filter have?

The selection of the precision filter is matched with the total water intake, and the diameter of the precision filter is selected according to the total water intake. For 40"5um filter precision filter, the single water production is approximately 2m3/h.

The types of filter elements are roughly polypropylene filter, honeycomb filter, spray-molded filter, and folding filter.

8. How to remove iron in water?

The iron in groundwater is generally divalent ferrous iron, so the divalent ferrous iron must be oxidized to ferric iron. The oxidation process is completed by aeration. The aeration device makes the water fully contact with oxygen to produce natural oxidation. The water after the gas is subjected to a de-ironing process by a iron and manganese removal filter. If the iron in the water is mostly trivalent iron, it is not necessary to aerate and directly enter the iron and manganese removal filter for removal.

9. Why do some water types need to be added or removed after passing through the cation exchanger?

As a result of the exchange of metal ions in the water with the H+ ions on the cation resin, the H+ ions enter the water, so the effluent of the cation exchanger is acidic, converting most of the HCO3- in the water into H2CO3 and further converting it into CO2 gas.

Due to the low solubility of CO2 gas, one provides good conditions for degassing. Second, if degassing is not performed, H2CO3 will be exchanged with anion exchange resin, which increases the burden on the anion exchanger and shortens the anion exchanger. The production cycle.

Usually, after the carbon dioxide device is placed in the cation exchanger, before the anion exchanger, there are some pre-desalting systems such as reverse osmosis, and some places do not need to add carbon dioxide, all of which depend on the user's water quality. set.

10. How many ways to prevent corrosion?

Anti-corrosion methods include lining rubber, epoxy, lining plastic, enamel and other anti-corrosion methods.

11. What are the reverse osmosis devices mainly composed of?

The reverse osmosis device is mainly composed of a high pressure pump, a high pressure pump outlet gate valve (manual or electric), a high and low pressure protection switch, a water inlet flow meter (also not added), a water production flow meter, a concentrated water flow meter, a water producing conductivity meter, and a membrane module. (pressure vessel, reverse osmosis membrane element), concentrated water electric valve, concentrated water shut-off valve, inlet water pressure gauge, interstage pressure gauge, concentrated water pressure gauge, water pressure gauge, reverse osmosis bracket, reverse osmosis control disc, reverse Penetrate the sampling disk, rupture film and corresponding pipes, clamps, elbows, etc.

12. What kinds of instruments must be used in the reverse osmosis system?

Several instruments and instruments are required in the reverse osmosis system:

1) Pollution Index Meter: The SDI index used to measure system pretreatment.

2) Concentrated water flow meter: used to measure the flow rate of concentrated water in the system, and used in conjunction with the water flow meter to determine the system recovery rate.

3) Water production flow meter: used to measure the flow rate of system water production. Water conductivity meter: used to measure system water quality (conductivity)

4) Pressure gauge: measure the inlet pressure of the system, the pressure between the sections, the pressure of the concentrated water, and the pressure of the produced water.

5) Inlet flow meter: used to measure the total influent flow of the system.

6) Thermometer: used to measure the temperature at which the system is operating.

7) Influent PH meter: used to measure the change of the influent pH value of the system.

8) Influent conductivity meter: used to measure the inlet conductivity of the system, and the water conductivity is used together to determine the system desalination rate.

9) Redox instrument: used to measure the amount of oxidizing substances in the system's influent water to determine the degree of threat to system safety.

10) High and low voltage protection switch: used to protect the system from running under low pressure (insufficient water supply) and high pressure.

A reverse osmosis system is more complex, and the instrumentation used is determined by process requirements and user investment. A normal reverse osmosis system only requires a water flow meter, a concentrated water flow meter, a water producing conductivity meter, a pressure gauge, and high and low pressure protection.

13. What parts of the electrodialysis unit are made up of? What are the characteristics and functions of each part?

Electrodialysis unit is composed of several parts, anion, abdomen, separator, electrode, clamping device, leak-proof rubber sheet, pickling system, flow meter, pressure gauge, ABS pipe fittings, valve, thyristor rectifier cabinet.

The selective permeability of the anion and the yang membrane to the ions in the water makes the system have concentrated water, fresh water and extreme water, which is the desalting part of the device.

The main material of the separator is polypropylene, which acts to support the amnion and form a thick water chamber.

The electrode primarily forms the electric field required for the ion exchange membrane. The electrode consists of a cloth head, a perforated plate and a PVC frame.

The clamping device mainly fixes the anion-cation exchange membrane, the electrode, the separator and the like to make it a whole.

The leak-proof rubber sheet is between the electrode and the separator to prevent the system from leaking water at the electrode side.

The pickling system is an integral part of the entire plant. When the electrodialysis unit produces an abnormal phenomenon such as a decrease in the salt rejection rate, a decrease in the water production amount, and an increase in the operating pressure, it should be judged by the reason that the system is composed of a chemical agent such as scale, inorganic matter plugging, organic matter fouling, etc. Perform chemical cleaning.

The thyristor rectifier cabinet is the energy feeding part of the device, which is to rectify the power frequency alternating current through the thyristor rectifier device into a voltage adjustable DC voltage, and add a DC electric field in the film stack to pull the yin and yang in the solution. The ions produce directional movement. The main parameters of the thyristor rectifier cabinet are: rectified voltage, operating current and rectified power. Flowmeters, pressure gauges, ABS pipe fittings, and valves are accessory accessories for electrodialysis, which function to show various operating parameters of the electrodialysis unit, the connection of the water chamber, and the switching of the direction of water flow.

14. What are the advantages and disadvantages of electrodialysis?

The disadvantages of electrodialysis are:

Low energy consumption and small footprint.

Simple operation and low noise.

The effluent water quality is stable and there is no phase change during the desalination process.

The polluted environment is small.

The scope of application is 200-40000mg/h.

The disadvantages of electrodialysis are:

Installation is more complicated.

The desalination effect is not quite complete, generally 75%.

The water recovery rate is generally 50%.

15. What is the principle of desalination for electrodialysis?

The anion-cation exchange membrane in the electrodialysis device has selective permeability, and when the ions in the solution are orientated by the electric field, the selective exchange permeability of the anion-cation exchange membrane is transmitted through or not through the corresponding exchange membrane. Concentrated or fresh water is formed in different water chambers.

16. What is the approximate ratio of concentrated, light and polar water distribution in electrodialysis?

The distribution ratio of concentrated water, fresh water and polar water in the electrodialysis unit is roughly 4:4:2, so the measures for saving the extreme water in the electrodialysis desalination system are very meaningful; the measures for saving the extreme water are partially used. Concentrated water acts as a polar water for discharge or uses extreme water circulation; the polar water circulation system is specifically a soft water or desalinated water + NaCL solution acting as an extreme water cycle.

17, how to choose a good yin and yang heterogeneous ion exchange membrane

A good quality heterogeneous ion exchange membrane must have the following characteristics:

1) Choose strong permeability. Selectivity is the main indicator for measuring membrane performance. It directly affects the current efficiency and desalination effect of the electrodialyzer. Its selective permeability is greater than 85%.

2) The membrane resistance is small. The electrodialyser consists of several hundred pairs of ion exchange membranes, so the membrane resistance accounts for a large proportion of the total resistance. If the resistance is small, the operating voltage is low and the current efficiency is high.

3) Strong chemical stability. During the migration of anions and cations, the concentrated water solution will form a concentrated ion solution; when polarization occurs, the PH value of the retention layer on both sides of the membrane will also change, especially when the polar water participates in the chemical reaction to produce an oxidizing pole. Strong oxygen and chlorine, so the membrane must be required to have strong chemical stability to extend the life of the electrodialyzer.

4) Strong mechanical strength and dimensional stability.

5) Lower diffusion performance.

6) High removal effect on strong electrolytes.

18. What material is the electrodialyzed electrode made of? What are the specifications? What are the advantages and disadvantages of each?

Electrodialysis electrodes are divided into several types: titanium-plated platinum electrode, titanium-coated ruthenium electrode, graphite electrode, and stainless steel electrode; the electrode varies according to the size of the electrodialysis body. Common engineering electrode specifications are: 800×1600mm, 400 × 1600 mm, 400 × 800 mm, 340 × 640 mm, etc.

Different electrode materials have different characteristics:

1) Titanium-plated platinum electrode: Corrosion resistance is quite good, can be used under very harsh conditions, but platinum is expensive and has fewer resources, which limits its promotion in China.

2) Titanium-coated ruthenium electrode: a compound coated with ruthenium (Ru), iridium (Ir) or titanium (Ti) on a titanium substrate, which is formed into a mixed oxide after high temperature treatment; due to ruthenium (Ru), iridium (Ir) Titanium (Ti) has very close ionic radii, and the lattice structure and space group belong to the same type. Therefore, a solid solution of RuO2-IrO2-TiO2 can be formed in the co-oxidation of heat treatment, which has excellent corrosion resistance and is suitable as an electrode. material.

3) Graphite electrode: Graphite electrode is easily corroded, mainly due to chemical corrosion and mechanical wear; when graphite is used as anode, graphite is oxidized to CO2 or CO due to anodization, causing its crystal structure to be damaged and damaged;

In the electrodialysis unit, the loss of graphite electrode is mainly caused by mechanical action. The high-flow polar water has a strong scouring effect on graphite. On the other hand, the gas generated by the electrode reaction has an impact on graphite, plus electrochemical corrosion. It often causes the graphite particles to peel off and pollute the water quality and even block the water channel; with the appearance of the titanium-coated electrode, the graphite electrode has gradually been eliminated.

4) Stainless steel electrode: Generally speaking, stainless steel is only used as a cathode and cannot be used as an anode. Otherwise, since the natural water contains a lot of chlorine ions, the anode of the stainless steel dissolves to form divalent iron, nickel and chromium ions.

The correct choice of electrode materials is of great significance for extending the life of the electrode, reducing system investment and operating costs. For different water quality, different materials can be used:

1) For natural water containing chloride as a main component, a titanium-coated ruthenium electrode is preferred.

2) For natural water with sulphate as the main component, lead plate, stainless steel, and titanium coated ruthenium electrode are preferred.

3) For natural water containing calcium bicarbonate as the main component, stainless steel or titanium coated ruthenium electrode is preferred.

4) For the natural water of mixed ions, it is preferred to use titanium coated graphite, graphite and titanium coated platinum electrodes.

19. What is the concentration polarization phenomenon of electrodialysis? What are the hazards of concentration polarization?

When the working current of electrodialysis exceeds the limit current, water electrolysis occurs at the interface between the anion exchange membrane and fresh water, and H+ and OH- ions are generated, so that polarization is generated when these ions participate in the charge transfer.

The hazard of polarization is simply to make a kind of electric energy consumed on the electrolysis water unrelated to desalting, thus causing waste of electric energy, and OH- ions enter the concentrated water chamber and CO32- and CaCO3 scale, so that the membrane and electrodialysis The performance is degraded.

When polarized, the concentration of electrolyte ions on the membrane surface of the desalting chamber is much lower than that of the main solution, causing a high polarization potential, while the membrane concentration of the concentrated water chamber is much higher than the concentration of the main solution, making the water easy to form precipitates. The ions precipitate on the film surface, and as a result, the apparent resistance of the film increases remarkably, the current density decreases, and the salt rejection rate decreases. Current efficiency drops because a large part of the current is consumed in the electrolysis of water

|

|

About Us

About Us Vision

Vision Corporate culture

Corporate culture Corporate video

Corporate video Service mode

Service mode

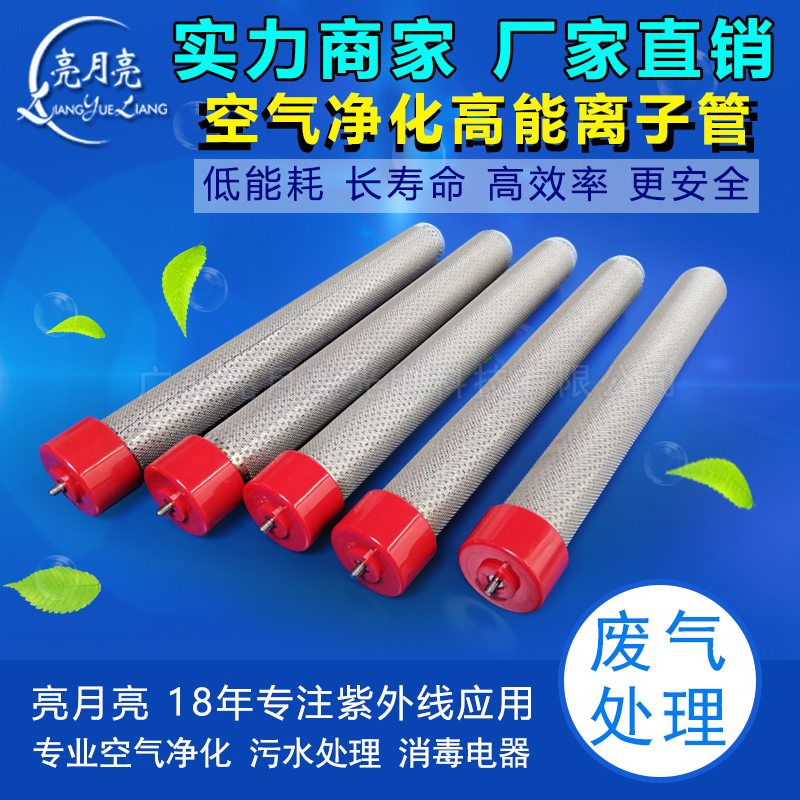

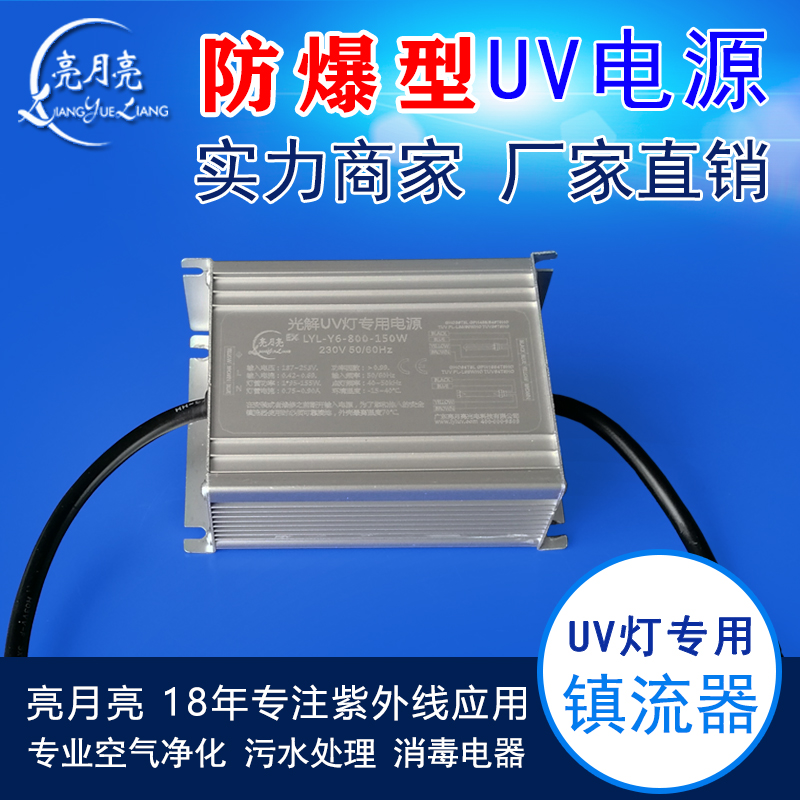

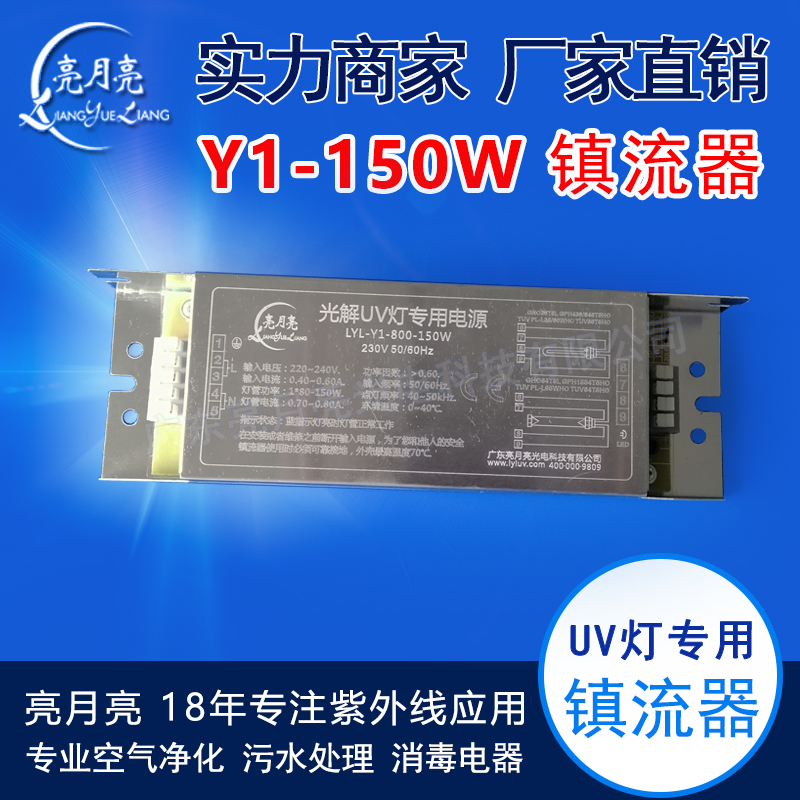

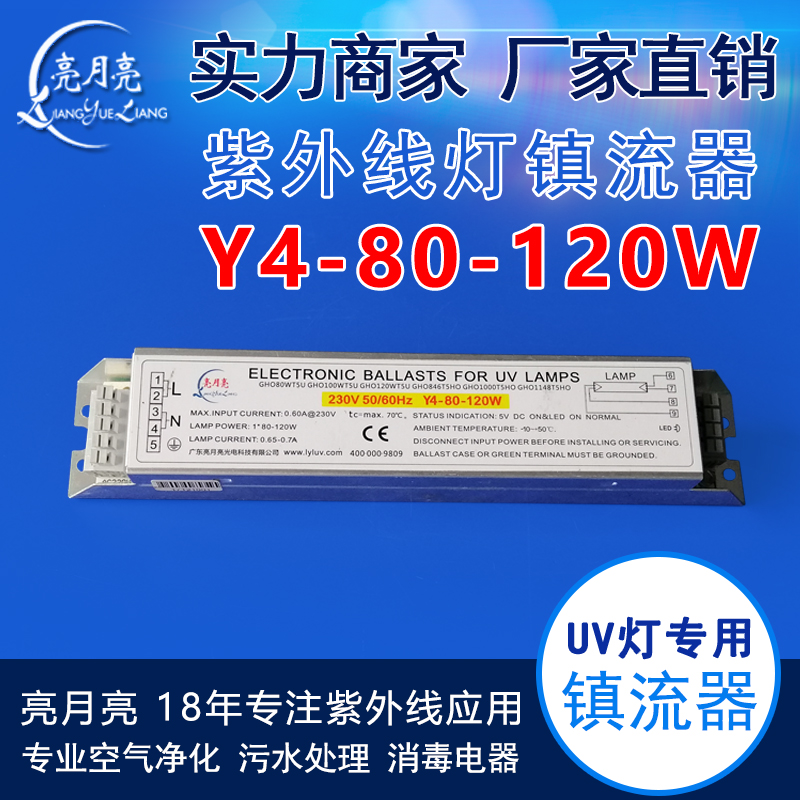

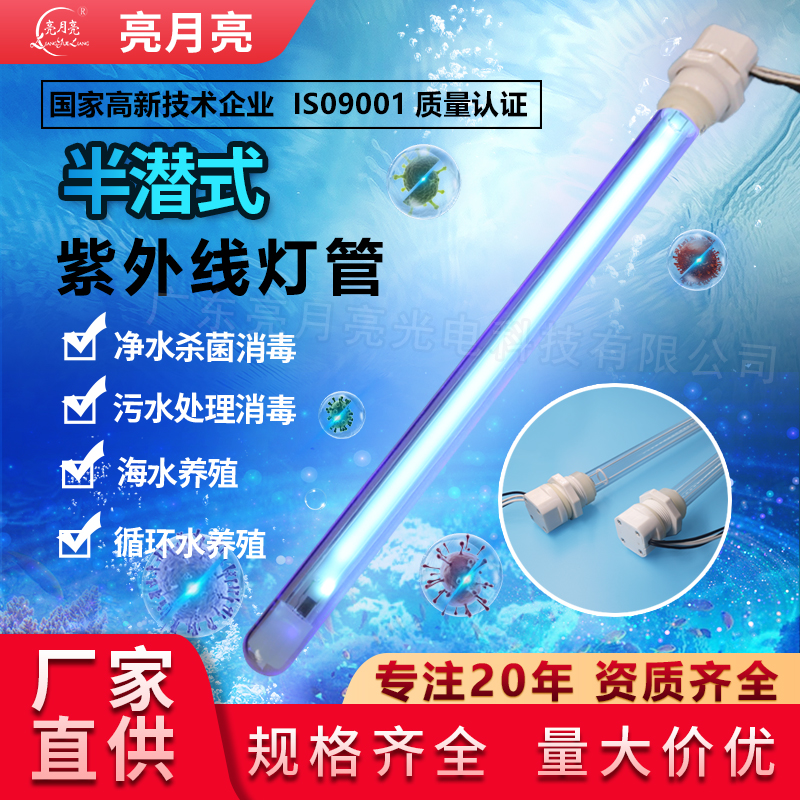

1554mm waste gas sewage treatment ultraviolet germicidal lamp

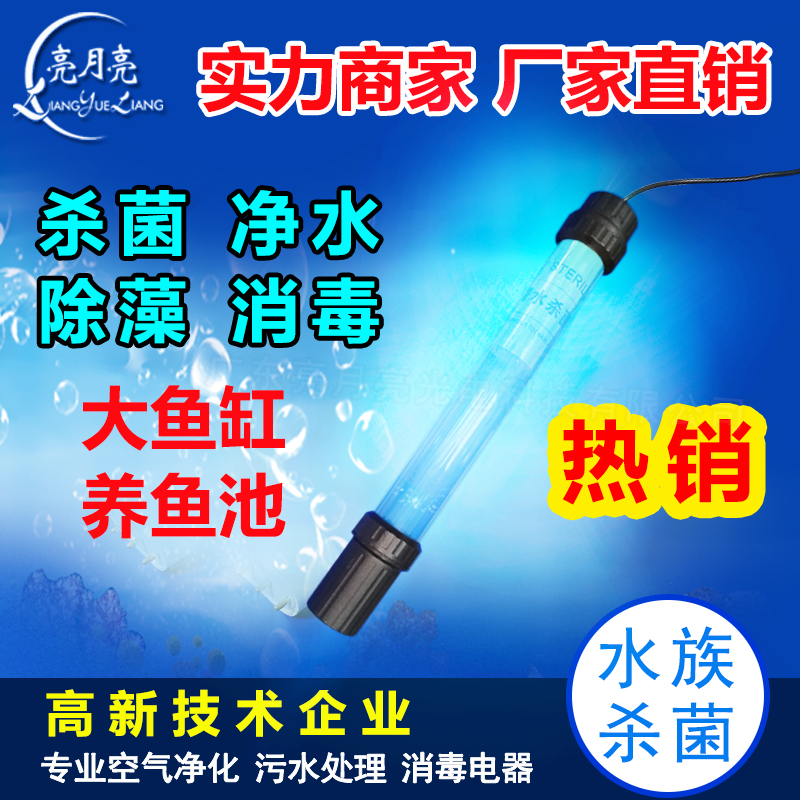

1554mm waste gas sewage treatment ultraviolet germicidal lamp Aquarium Aqua UV germicidal lamp

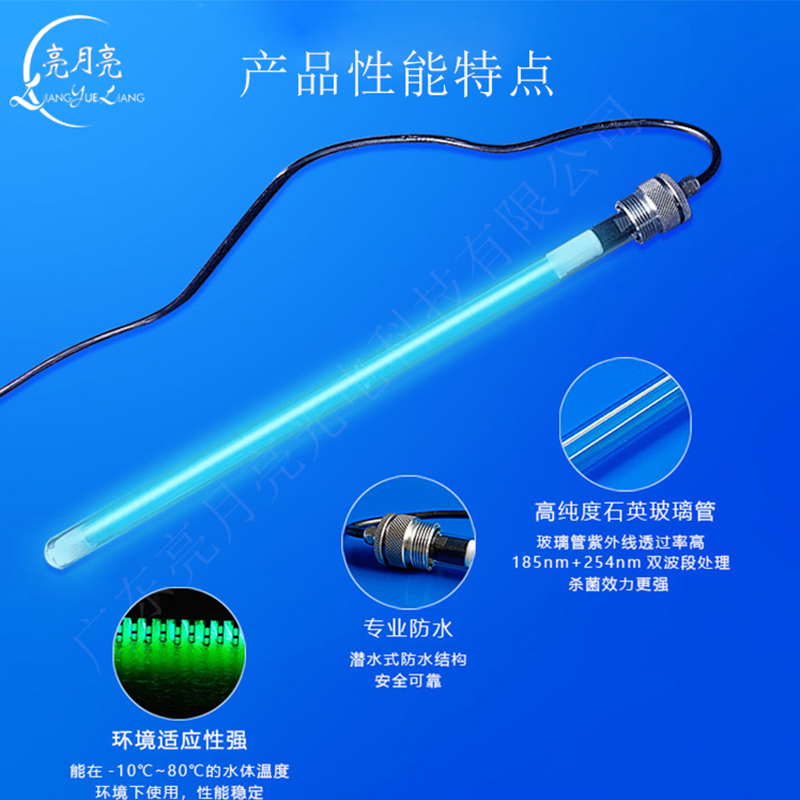

Aquarium Aqua UV germicidal lamp Metal head 100W full submersible water treatment lamp

Metal head 100W full submersible water treatment lamp