The flue gas desulfurization facilities that have been built at home and abroad are mostly coal-fired power plants. The research on desulfurization technology is also based on power plants. The research on desulfurization technology of petroleum refinery enterprises can learn from the mature technology of flue gas desulfurization of power plants to some extent. At present, according to the form of by-products, flue gas desulfurization technology can be divided into three types: wet method, dry method and semi-dry method.

Wet flue gas desulfurization technology (WFGD)

The absorbent reacts with SO2 in a liquid state, and the desulfurization product is also in a liquid state. The method has high desulfurization efficiency and stable operation, but the investment and operation and maintenance costs are high, the system is complicated, and the product after desulfurization is difficult to handle, and it is easy to cause secondary pollution.

Advantages of wet flue gas desulfurization technology: Wet flue gas desulfurization technology is gas-liquid reaction, with fast reaction speed and high desulfurization efficiency, generally higher than 90%, mature technology and wide application. The wet desulfurization technology is relatively mature, and the production operation is safe and reliable. It has always dominated many desulfurization technologies, accounting for more than 80% of the total installed capacity of desulfurization. Disadvantages: the product is liquid or sludge, it is difficult to handle, the equipment is corrosive, the flue gas needs to be reheated after washing, high energy consumption, large floor space, high investment and operation cost, complicated system, huge equipment, water consumption Large, one-time investment is high, generally applicable to large power plants. Classification: Commonly used wet flue gas desulfurization technologies include limestone-gypsum method, indirect limestone-gypsum method, and lemon absorption method.

Limestone

A[Y)I~](ZC9Z[3Y)IDK7LK.gif)

me-gypsum method

The limestone or lime slurry is used to absorb SO2 in the flue gas to form calcium sulfite. The separated calcium sulfite (CaO3S) can be discarded or oxidized to calcium sulfate (CaSO4) and recovered as gypsum. This is the most mature technology in the world with the most stable desulfurization process, and the desulfurization efficiency is over 90%.

Indirect limestone-gypsum method

Common indirect limestone-gypsum methods are: sodium alkali double alkali method, alkaline aluminum sulfate method and dilute sulfuric acid absorption method. Principle: Sodium alkali, alkaline alumina (Al2O3 ̇nH2O) or dilute sulfuric acid (H2SO4) absorbs SO2, and the resulting absorption liquid reacts with limestone to regenerate and form gypsum. The method is simple in operation, less secondary pollution, no scaling and clogging problems, high desulfurization efficiency, but the quality of the produced gypsum products is poor.

Lemon absorption method

Principle: The citric acid (H3C6H5O7 ̇H2O) solution has good buffering performance. When the SO2 gas passes through the citrate liquid, the SO2 in the flue gas reacts with the H+ in the water to form the H2SO3 complex, and the SO2 absorption rate is above 99%. . This method is only suitable for low concentration SO2 flue gas, and is not suitable for high concentration SO2 gas absorption, and the application range is narrow. In addition, there are wet flue gas desulfurization technologies such as seawater desulfurization method, ammonium phosphate compound fertilizer method, and liquid phase catalytic method.

Dry flue gas desulfurization technology (DFGD)

Both the desulfurization absorption and the product treatment are carried out in a dry state. The method is simple, no sewage and waste acid is discharged, equipment corrosion is small, operation cost is low, but desulfurization efficiency is low.

Advantages of dry flue gas desulfurization technology: dry flue gas desulfurization technology is gas-to-liquid reaction. Compared with wet desulfurization system, it has simple equipment, small floor space, low investment and operating cost, convenient operation and low energy consumption. The product is easy to handle and has no sewage treatment system. Disadvantages: Slow reaction rate, low desulfurization rate, advanced 60~80%. However, at present, the desulfurization efficiency of the method is low, the utilization rate of the absorbent is low, the wear and scale phenomenon are serious, the difficulty in equipment maintenance is large, the stability and reliability of the equipment operation are not high, and the service life is short, which limits The application of this method.

Classification: Commonly used dry flue gas desulfurization technologies include activated carbon adsorption, electron beam irradiation, charged dry absorbent spraying, and metal oxide desulfurization. A typical dry desulfurization system is to spray a desulfurizing agent (such as limestone, dolomite or hydrated lime) directly into the furnace. Taking limestone as an example, when calcined at a high temperature, the desulfurizing agent is calcined to form porous calcium oxide particles, which react with SO2 in the flue gas to form calcium sulfate, thereby achieving the purpose of desulfurization.

Activated carbon adsorption

Principle: SO2 is adsorbed by activated carbon and catalytically oxidized to sulfur trioxide (SO3), which is then reacted with water to form H2SO4. The saturated activated carbon can be regenerated by water washing or heating to form dilute H2SO4 or high concentration SO2. By-product H2SO4, liquid SO2 and elemental S can be obtained, which can effectively control the emission of SO2 and recover sulfur resources. The technology has been improved by activated carbon at Xi'an Jiaotong University, and ZL30 and ZIA0 with low cost and strong adsorption performance have been developed. The process of activated carbon has been further improved, so that the adsorption rate of SO2 in the flue gas reaches 95.8%, reaching the national emission standard.

Electron beam irradiation

Principle: The high-energy electron beam is used to irradiate the flue gas to generate a large amount of active substances, which oxidize SO2 and nitrogen oxides in the flue gas to SO3 and nitrogen dioxide (NO2), further generate H2SO4 and nitric acid (NaNO3), and are ammonia ( NH3) or limestone (CaCO3) absorbent absorption.

Charged dry absorbent spray desulfurization

Principle: The absorbent flows at a high speed through the high-voltage electrostatic corona charging zone generated by the spraying unit, so that the absorbent has an electrostatic charge. When the absorbent is sprayed into the flue gas stream, the absorbent repels each other due to the same kind of electric charge. Fully exposed, so that the efficiency of desulfurization is greatly improved. The method is dry treatment, no equipment pollution and scaling phenomenon, no waste industrial flue gas desulfurization technology research progress water waste residue, by-products can also be used as fertilizer, no secondary pollutants are produced, the desulfurization rate is greater than 90%, and the equipment Simple and adaptable. However, this method desulfurization relies on an electron beam accelerator to generate high-energy electrons; for a large-scale enterprise in general, a high-power electron gun is required to be harmful to the human body, so radiation shielding is also required, so operation and maintenance requirements are high. An electric desulfurization unit was built in Chengdu Thermal Power Plant in Sichuan, and the desulfurization of SO2 in flue gas reached the national emission standard.

Metal oxide desulfurization

Principle: According to the characteristics of SO2, a relatively active gas, oxides such as manganese oxide (MnO), zinc oxide (ZnO), iron oxide (Fe3O4) and copper oxide (CuO) have strong adsorption to SO2. At normal temperature or low temperature, the metal oxide adsorbs SO2. At high temperature, the metal oxide reacts with SO2 to form a metal salt. Then, the adsorbate and the metal salt are regenerated by a thermal decomposition method, a washing method, or the like. This is a dry desulfurization method. Although there is no sewage, waste acid, and no pollution, this method has not been promoted, mainly because the desulfurization efficiency is relatively low, the equipment is large, the investment is relatively large, the operation requirements are high, and the cost is high. .

The key to this technology is the development of new adsorbents. The above several SO2 flue gas treatment technologies are widely used at present. Although the desulfurization rate is relatively high, the process is complicated, the operation cost is high, the anti-pollution is not complete, and secondary pollution is caused, which is inconsistent with China's economic and environmental development. Incompatible, it is necessary to explore and study new desulfurization technologies.

Semi-dry flue gas desulfurization technology (SDFGD)

The semi-dry flue gas desulfurization technology (SDFGD) semi-dry method takes advantage of the wet method and the dry method. The desulfurization agent is desulfurized in a wet state, and the desulfurization product is discharged in a dry state. The method not only has the advantages of high speed of wet desulfurization reaction and high desulfurization efficiency, but also has the advantages of dry sewage and waste acid discharge, and easy treatment of sulfur products.

Semi-dry flue gas desulfurization technology Semi-dry desulfurization includes spray drying desulfurization, semi-dry and semi-wet desulfurization, powder-particle spouted bed desulfurization, flue jet desulfurization and the like.

Spray drying desulfurization

The force of the mechanical or airflow is used to disperse the absorbent into very fine mist droplets. The mist droplets form a relatively large contact surface area with the flue gas, and a heat exchange and mass transfer occurs between the gas and liquid phases. And the desulfurization method of chemical reaction. The commonly used absorbents are lye, lime milk, limestone slurry, etc. Most of the devices currently use lime milk as an absorbent. Under normal circumstances, the desulfurization rate of this method is 65% to 85%.

Its advantages: desulfurization is carried out in the gas, liquid and solid three-phase state, the process equipment is simple, the product is dry CaSO4, CaSO4, easy to handle, no serious equipment corrosion and blockage, and less water consumption.

Disadvantages: The automation requirements are relatively high, the amount of absorbent is difficult to control, and the absorption efficiency is not very high. Therefore, choosing to develop a reasonable absorbent is a new problem to solve this method.

Semi-dry and semi-wet method

The semi-dry and semi-wet method is a desulfurization method between the wet method and the dry method. The parameters such as desulfurization efficiency and desulfurizer utilization rate are also between the two. This method is mainly applicable to the flue gas treatment of small and medium boilers. . The characteristics of this technology are: low investment, low operating cost, although the desulfurization rate is lower than the wet desulfurization technology, it can still reach 70% tn, and the corrosion is small, the floor space is small, and the process is reliable. Compared with the wet desulfurization system, the semi-dry and semi-wet desulfurization system commonly used in the industry eliminates the pulping system and converts the Ca(OH)2: aqueous solution injected into the wet desulfurization system into CaO or Ca ( OH) 2 powder and water mist. Compared with the dry desulfurization system, it overcomes the shortcomings of low reaction efficiency and long reaction time of SO2 and CaO in the furnace calcium injection method, improves the utilization rate of the desulfurizer, and has simple process and good development prospect.

Powder - particle spouted bed desulfurization

Technical principle: The flue gas containing SO2 passes through the preheater and enters the spouted bed of the powder. The desulfurizing agent is powdered and mixed with water in advance, and is continuously sprayed into the bed from the top of the spouted bed in the form of slurry, and the spouting particles Mix thoroughly, and by means of contact with hot flue gas, desulfurization and drying are carried out simultaneously. The product after the desulfurization reaction is blown out of the separator in the form of a dry powder. This desulfurization technology uses limestone or hydrated lime as a desulfurizer. It has a high desulfurization rate and desulfurizer utilization rate, and has little impact on the environment. However, there are strict requirements between the inlet air temperature, the relative humidity in the bed, and the reaction temperature. When the moisture content of the slurry and the reaction temperature are not properly controlled, there is a phenomenon that the desulfurizing agent sticks to the wall.

Flue jet semi-dry method

Flue gas desulfurization This method utilizes the flue between the boiler and the dust collector as a reactor for desulfurization. It does not need to add an absorption container, which greatly reduces the process investment, is simple in operation, requires a small space, and is suitable for development and application in China. Semi-dry flue gas injection flue gas desulfurization means spraying the absorbent slurry into the flue, and the slurry is reacted while evaporating, and the reaction product is discharged into the flue with dry powder.

New desulfurization technology

New technologies for desulfurization In recent years, technology has advanced by leaps and bounds, and environmental issues have risen to legal heights. China's science and technology workers have developed some new desulfurization technologies, but most of them are still in the experimental stage and need to be further verified by industrial applications.

Sodium sulfide desulfurization

The sodium sulfide desulfurization method developed by Outokumpu mainly uses industrial grade sodium sulfide as a raw material to absorb SO2 industrial flue gas, and the product is aimed at generating sulfur. The reaction process is quite complicated. Na2SO4, Na2SO3, Na2S203, S, Na2Sx and other substances are formed. It can be seen from the product that the process consumes a high energy and the value of by-products is low. The Shilin of South China University of Technology has shown that various sulfurs in the process have been studied. The content of the compound changes with the change of the reaction conditions, the pH value of the solution is controlled between 5.5 and 6.5, and a small amount of the additive TFS for oxidation is added. The product mainly produces Na2S203, and the 5H20 ̇Na2S203 with high added value can be obtained by filtration and evaporation. And the desulfurization rate is as high as 97%, and the reaction process is: SO2+Na2S=Na2S203+S. This new desulfurization technology has passed the pilot test and is being applied.

Membrane absorption method

Membrane separation technology represented by organic polymer membrane is a new gas separation technology developed in recent years and has been widely used, especially in the purification and treatment of water. Researchers such as Jin Mei from the Dalian Institute of Material Science and Technology of the Chinese Academy of Sciences have creatively used membranes to absorb and remove SO2 gas, and the effect is relatively remarkable, and the desulfurization rate is 90%.

The process is: they use a polypropylene hollow fiber membrane absorber, using NaOH solution as the absorption liquid to remove SO2 gas, which is characterized by using a porous membrane to separate the gas SO2 gas from the NaOH absorption liquid, and the SO2 gas reaches through the pores in the porous membrane. At the gas-liquid phase interface, SO2 reacts rapidly with NaOH to achieve the purpose of desulfurization. This method is a new technology combining membrane separation technology and absorption technology, with low energy consumption, simple operation and low investment.

Microbial desulfurization technology

According to the microbial participation in the various processes of the sulfur cycle, and the energy is obtained, the microbial flue gas desulfurization is carried out by the mechanism: under the aerobic condition, the SO2 in the flue gas is oxidized to sulfuric acid by the indirect oxidation of the desulfurized bacteria. The bacteria get energy from it. Compared with traditional chemical and physical desulfurization, biological desulfurization basically has no external conditions such as high temperature, high pressure and catalyst. It is operated under normal temperature and pressure, and the process flow is simple and there is no secondary pollution. It has been based on the removal of 5t of H2S per day from geothermal power stations in foreign countries; the total cost of calculating microbial desulfurization is 50% of the conventional wet method. Regardless of whether it is organic sulfur or inorganic sulfur, inorganic sulfur SO2 which is indirectly utilized by microorganisms can be generated upon combustion. Therefore, the development of microbial flue gas desulfurization technology has great potential. Wang An and others from Sichuan University used ferrooxidans for desulfurization research under laboratory conditions. At a lower liquid-gas ratio, the desulfurization rate was 98%.

About Us

About Us Vision

Vision Corporate culture

Corporate culture Corporate video

Corporate video Service mode

Service mode

1554mm waste gas sewage treatment ultraviolet germicidal lamp

1554mm waste gas sewage treatment ultraviolet germicidal lamp Aquarium Aqua UV germicidal lamp

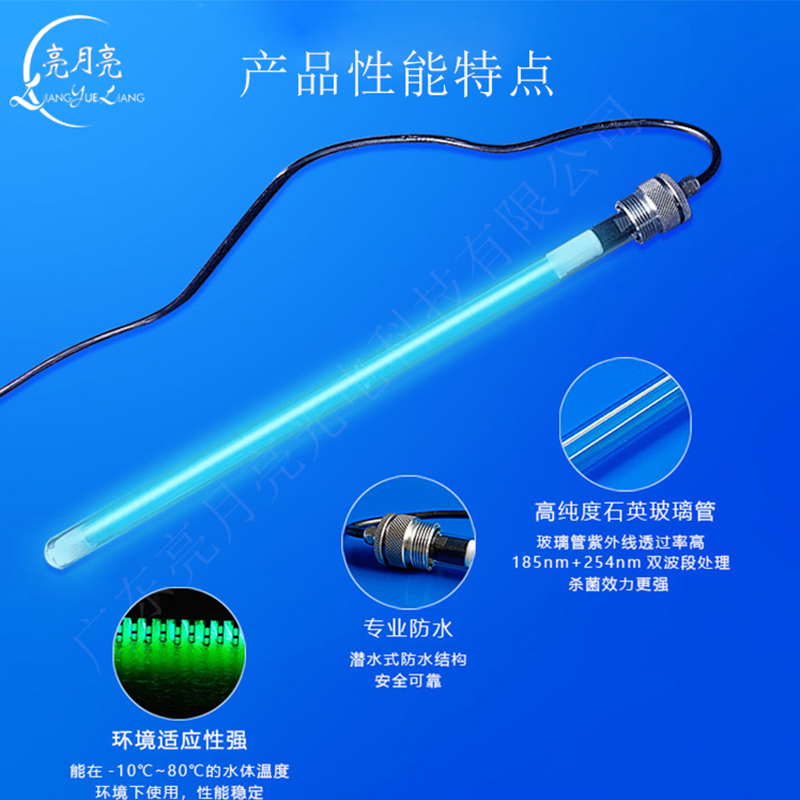

Aquarium Aqua UV germicidal lamp Metal head 100W full submersible water treatment lamp

Metal head 100W full submersible water treatment lamp

A[Y)I~](ZC9Z[3Y)IDK7LK.gif) me-gypsum method

me-gypsum method